System overview

ERP.net Production

The production modules of the ERP.net provide an opportunity for material and capacity planning, organization and keeping track of production schedules. It makes it way easier to log and report invested resources and reported production by an option to define product specifications and production technologies. Recognizing the added value in multi-stage production is easy and fully controlled. Linking production to the product configurator provides all the advantages of quick defining and valuation of new products in accordance with customer requirements.

Learn about the benefits

ERP.net provides flexible tools for the execution of different types of production with a high level of planning and automation of production processes.

Provides

the option to log any type of production

The option

for graphical representation of capacity planning (Gantt chart)

Integration

of production with the other functional units

Automated

warehousing

Modules

ERP.net ERP

The Production system of ERP.net covers the following production modules:

-

- makes it possible to define a lead technology for each product group, and based on that, to create a recipe for the production of each product;

- product technology includes all necessary data for the manufacturing of the product: necessary materials, production stages, production operations (time and resources), necessary resources (people and machines)

- option to adjust technologies and versions archive – upon changes in interchangeable raw materials or by-products, or changes to the amount of raw materials used

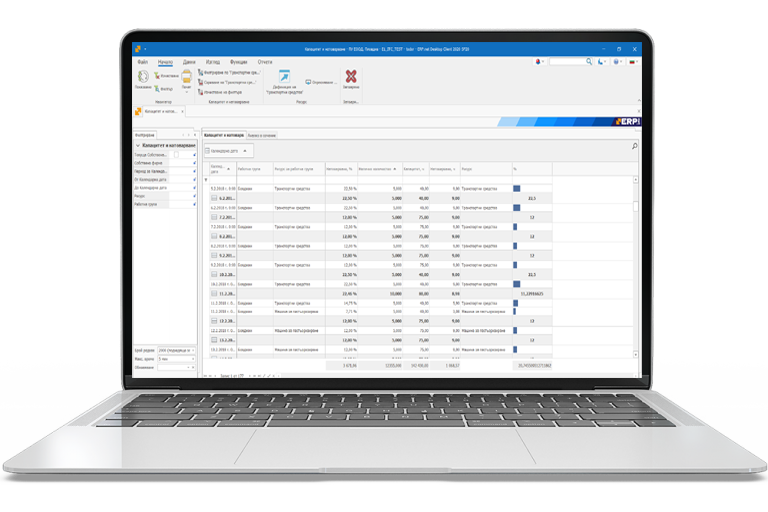

-

- manufacturing and resource planning (MRP) – intended to provide the necessary products and materials in the right place, at the right time; in case of inventory shortages, the system sends an alert and offers suggestions for supply

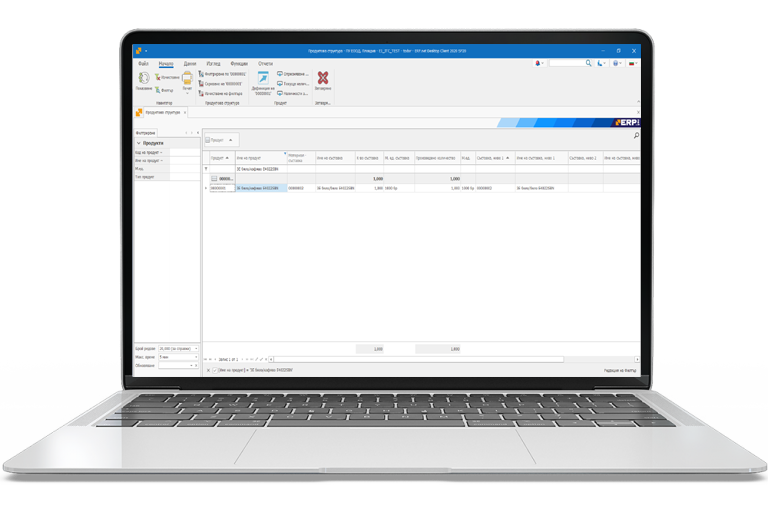

-

-

- monitors the utilization of production resources, production activity log and the creation of a Gantt schedule for production

-

- document flow management in the production process – keeping track of planned production, control of input resources, reporting of completed activities (input materials and operations) and completed production