Versatile use cases

The autonomous multifunctional robot has applications across various industries, including automotive manufacturing, food processing, healthcare, pharmaceuticals, packaging, printing, manufacturing, and more. This robot is designed to perform a range of tasks that enhance the efficiency of production and logistics processes.

The autonomous multifunctional robot can move finished products from the end of production lines to storage facilities, deliver raw materials from warehouses, and transfer materials between different stages of production. Additionally, the robot can replace transitional conveyors and belts, offering flexible material handling solutions.

In warehouses and distribution centers, the robot is used for order picking, transferring goods to workers (G2P), collecting individual items, and flexible sorting, making it a valuable tool for optimizing logistics operations and production processes.

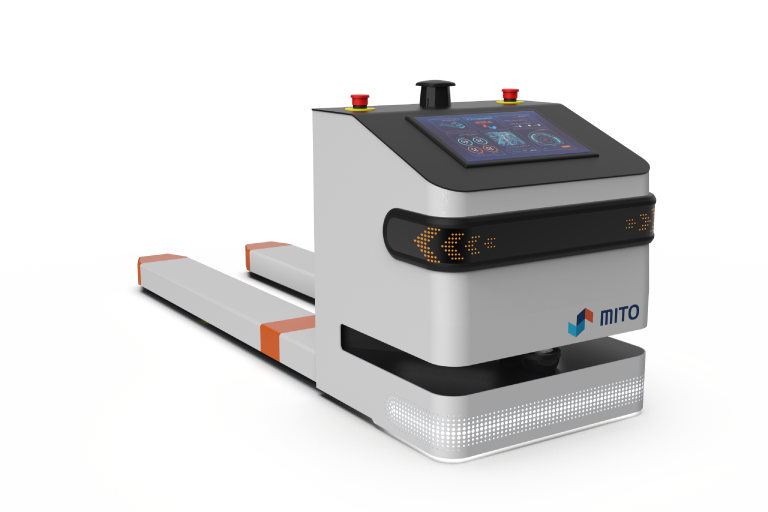

Pallet Truck

Stationary Platform

Lifting Platform

Lifting Rails

Pallet Lifting

Pick & Place Platform

Pick & Place Lifting

Shelf Platform

Roller/Conveyor Platform

Roller/Conveyor Pick & Place Platform

Easy, safe, and scalable multifunctional platform

The platform requires no programming and features an intuitive user interface

Functionality management with drag-and-drop

A digital replica of your physical components and system, enabling easy tracking and real-time management

The interface is intuitive and easy to use, making it simple to work with the platform

It uses AI to automatically manage complex processes

A flexible and modular solution that can be adapted to meet specific needs

Supports a fleet management system according to VDA 5050 and meets the safety standard PLd/SIL2

Equipped with an autonomous localization and navigation system with obstacle avoidance capabilities

Fast charging: just 12 minutes to provide 8 hours of operation

Technical specifications

The Autonomous Multifunctional Robot (AMHR) is a new type of autonomous robot that combines the functions of several different types of robots into one device.

It integrates the capabilities of Autonomous Mobile Robots (AMR), Automated Guided Vehicles (AGV), Goods Picking Robots (APR), and Industrial Mobile Robots (IMR).

This multifunctional platform is built on a modular basis, which means it can be easily configured and expanded according to needs.

Dimensions

1690x635x545mm

Battery

LiFePO4 with BMS, charging 12min for one typical working day

Safety

PLd/SIL2

Payload

500/1000/1500kg

Maximum driving speed

2m/s

Pallet recognition

AI based detection technology

Driving system

Differential drive

Fleet management

according VDA5050

Software

Digital twin, grafical interface, cloud based

Lifting system

Electromechanical units

Localization and Navigation

Autonomous multi-level sensing technology

Light signals

Colour based indication for working status

Advantages

Modular and compact design

The compact and slim design allows for easy movement through narrow corridors. The modular platform can be transformed into different structures for use in various applications. The robot is adaptable to different items such as pallets, cages, boxes, and shelves.

Pallet Recognition

Fast AI-based pallet recognition with high accuracy ensures a seamless and efficient workflow

Without work interruptions

Fast charging and a large battery capacity ensure over 12 hours of uninterrupted operation at speeds of up to 2 m/s.

Fleet Management

Fleet management according to VDA5050.

Simultaneous Localization and Mapping (SLAM)

Unique multi-layered sensing and perception of the environment. Automated route optimization. The robot can navigate using magnetic strips, painted lines, inductive wires, rails, reflectors, natural patterns, and more, with positioning accuracy of ±10 mm and 1°.

Battery

High safety standard battery, LiFePO4. Fast charging – 12 minutes for 8 hours of standard operation.

Software

Seamless integration with ERP and WMS systems.

Autonomous Multifunctional Robot

Discover how autonomous multifunctional robots can improve efficiency in your production and logistics processes. These robots are capable of transporting finished products, delivering raw materials, and replacing traditional conveyors, all while supporting various industries such as automotive, food processing, healthcare, and more.

If you’re looking to streamline your operations and optimize workflows, consider integrating these robots into your system. Their ability to assist with order picking, transferring goods to workers, and flexible sorting can significantly enhance your operational efficiency.

To learn more about how autonomous multifunctional robots can benefit your organization, please reach out to us. Let’s explore how this technology can support your operational goals.